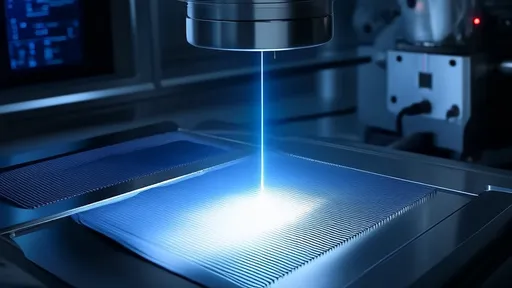

The textile industry has long relied on human inspectors to identify fabric defects, a process fraught with inconsistencies and inefficiencies. In recent years, the integration of artificial intelligence (AI) with microscopic precision has revolutionized fabric inspection, offering unprecedented accuracy in detecting even the most subtle imperfections. This technological leap is transforming quality control in textile manufacturing, ensuring higher standards and reducing waste.

Traditional fabric inspection methods often involve manual examination under controlled lighting conditions. Human inspectors, despite their expertise, are prone to fatigue and variability in judgment. Minor defects such as misweaves, stains, or yarn inconsistencies can be overlooked, leading to compromised product quality. AI-powered microscopic inspection systems address these challenges by combining high-resolution imaging with advanced machine learning algorithms, enabling real-time detection of flaws that escape the naked eye.

How AI-Driven Microscopy Works

The core of this innovation lies in the synergy between high-powered microscopes and convolutional neural networks (CNNs). Fabric samples are scanned at microscopic levels, capturing detailed images that are then analyzed by AI models trained on vast datasets of defect examples. These models can distinguish between acceptable variations in texture and actual defects, learning over time to improve their accuracy. The system flags anomalies with pinpoint precision, categorizing them by type and severity for further action.

One of the most significant advantages of this technology is its ability to adapt to different fabric types. Whether inspecting delicate silks, dense denims, or intricate knits, the AI system adjusts its parameters to maintain optimal detection rates. This flexibility is crucial for manufacturers producing diverse textile products, as it eliminates the need for multiple specialized inspection setups.

The Impact on Textile Manufacturing

Early adopters of AI-based fabric inspection report dramatic improvements in quality control metrics. Defect detection rates have soared to levels unattainable through manual methods, with some systems achieving 99.5% accuracy. This precision translates directly to reduced returns and increased customer satisfaction, as fewer flawed products reach the market.

Beyond quality assurance, the technology offers substantial economic benefits. By catching defects earlier in the production process, manufacturers minimize material waste and reduce the need for rework. The automated nature of the system also allows for faster throughput compared to manual inspection, addressing one of the traditional bottlenecks in textile production lines.

Challenges and Future Developments

Despite its advantages, implementing AI-powered microscopic inspection isn't without hurdles. The initial investment in equipment and training can be substantial, particularly for smaller manufacturers. There's also the challenge of integrating these systems with existing production lines, which often requires customized solutions.

Looking ahead, researchers are working to enhance these systems with more sophisticated capabilities. Emerging developments include 3D microscopic analysis for better assessment of surface irregularities and the integration of spectral imaging to detect color inconsistencies invisible under normal light. These advancements promise to push defect detection to even greater levels of precision.

The marriage of AI and microscopy represents more than just a technological upgrade—it signals a fundamental shift in how the textile industry approaches quality control. As these systems become more accessible and refined, they're poised to become the standard for fabric inspection across the global textile sector. Manufacturers who embrace this technology today position themselves at the forefront of an industry-wide transformation toward smarter, more efficient production methods.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025