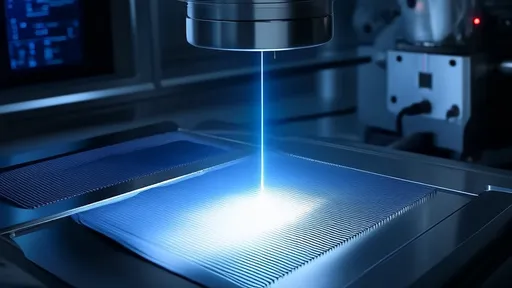

In a groundbreaking development that could revolutionize the fashion and textile industries, scientists have successfully demonstrated the ability to 3D bioprint living fur substitutes with programmable hair follicle orientation. This cutting-edge technology allows for the creation of customized pelts with precisely controlled hair flow patterns, opening up unprecedented possibilities for designers and manufacturers.

The process begins with harvesting specialized dermal papilla cells - the same cells responsible for hair growth in mammals. These cells are then mixed with a nutrient-rich bioink solution and carefully loaded into a modified bioprinter. What makes this approach revolutionary is the printer's ability to orient these cells during the deposition process, effectively "programming" the future direction of hair growth at the cellular level.

Traditional fur production has always been constrained by natural growth patterns, requiring extensive cutting and sewing to approximate desired hair flows. This new method allows designers to specify exact vector directions for hair alignment across different regions of the pelt, creating seamless transitions and customized patterns that would be impossible to achieve with conventional materials.

The implications extend far beyond aesthetic considerations. By controlling hair orientation at the microscopic level, researchers can engineer pelts with optimized thermal properties. Hair angled at 45 degrees, for instance, provides superior insulation compared to vertically-oriented follicles. This capability could lead to performance-optimized outerwear that maintains warmth without excessive bulk.

Ethical considerations have been at the forefront of this technology's development. Unlike traditional fur farming, the bioprinting process requires no animal slaughter. The cell sources can be obtained through harmless biopsies, and the resulting material is entirely cruelty-free. Some prototypes have even incorporated human hair follicle cells, suggesting a future where garments could be grown from a customer's own biological material.

Current prototypes measure approximately 10x10 cm, with hair densities comparable to premium natural furs. The lab-grown pelts demonstrate excellent durability in preliminary tests, maintaining their programmed hair orientation through multiple cleaning cycles. Researchers anticipate scaling up to full-sized panels suitable for garment production within the next 18 months.

Fashion houses have expressed keen interest in the technology's potential. Imagine coats where the hair naturally parts around seams or creates flowing patterns that respond to movement. The ability to "design" fur at this fundamental level could give rise to entirely new categories of textured fabrics and interactive garments.

Beyond fashion, medical applications are being explored. The same technology could produce skin grafts with properly oriented hair follicles for burn victims or create realistic prosthetics for patients undergoing reconstructive surgery. The precision control of hair direction proves particularly valuable for facial applications where natural-looking hair patterns are crucial.

As with any disruptive technology, challenges remain. Scaling up production while maintaining quality control presents engineering hurdles. Regulatory frameworks for biofabricated materials are still in their infancy. And consumer acceptance of lab-grown animal products continues to evolve. Nevertheless, the successful demonstration of controlled hair orientation marks a significant milestone in biomaterials engineering.

The research team has filed multiple patents covering both the bioprinting methodology and the specialized growth media that enables consistent follicle development. Several sustainable luxury brands have already entered into development partnerships, signaling strong industry confidence in the technology's commercial viability.

This innovation arrives at a pivotal moment for the fur industry, which has faced increasing scrutiny over animal welfare concerns and environmental impacts. Biofabricated fur offers a potential path forward - combining the desirable qualities of natural fur with ethical production methods and unprecedented design flexibility.

Looking ahead, researchers speculate about even more advanced applications. One tantalizing possibility involves creating pelts with dynamically adjustable hair orientations through embedded stimuli-responsive materials. Such "smart fur" could theoretically change its insulation properties or visual appearance in response to environmental conditions.

As the technology matures, we may soon see a new era of biomaterials where the boundary between grown and manufactured substances becomes increasingly blurred. The ability to program biological structures at this level of detail suggests profound implications not just for fashion, but for our fundamental relationship with biological materials in general.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025