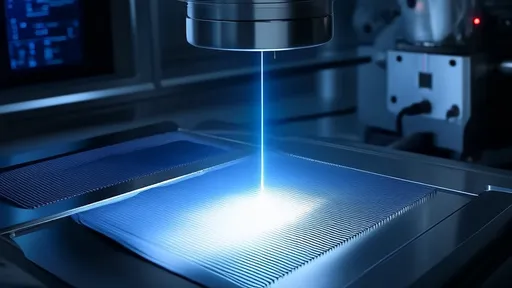

The textile industry, long criticized for its environmental footprint, is undergoing a quiet revolution. At the heart of this transformation lies an innovative approach to fabric coloring that eliminates water usage while delivering unprecedented precision. Laser-induced coloring technology represents a paradigm shift in how we think about dyeing processes, offering both sustainability and technological advancement in one package.

Traditional dyeing methods consume staggering amounts of water – approximately 200 tons of water per ton of fabric. The wastewater from these processes often contains toxic chemicals that pollute waterways and harm ecosystems. Laser-induced coloring completely bypasses this problematic system by using focused light energy to create colors directly on fabric surfaces without any liquid medium. This dry process not only conserves water but also removes the need for harmful chemical dyes.

The science behind this technology is as fascinating as its environmental benefits. High-precision lasers interact with the molecular structure of textiles to produce vibrant colors through physical and chemical changes at the fiber level. Unlike conventional dyes that sit on fabric surfaces, laser-induced colors become an integral part of the material itself. This results in exceptional colorfastness that withstands repeated washing and exposure to sunlight far better than traditionally dyed fabrics.

Manufacturers are particularly excited about the precision capabilities of this technology. Laser systems can create intricate patterns and color gradients with microscopic accuracy, opening new creative possibilities for designers. The same machine can switch between colors and patterns instantaneously without the cleaning or setup time required in conventional dye houses. This flexibility allows for mass customization – the ability to produce small batches or even single items economically.

From an industrial perspective, laser coloring systems offer significant operational advantages. The compact machinery requires far less factory space than traditional dyeing equipment, and the elimination of water processing means no need for large wastewater treatment facilities. Production speeds are faster as there's no drying time required after coloring. Perhaps most importantly, the technology enables localized production near fashion centers rather than being restricted to regions with abundant water supplies.

Early adopters in the sportswear and luxury fashion sectors have begun incorporating laser-colored fabrics into their collections. Performance apparel brands value the technology's ability to maintain color integrity during intense physical activity and frequent washing. High-end fashion houses appreciate the design possibilities and the compelling sustainability story they can share with environmentally conscious consumers.

While the technology shows tremendous promise, challenges remain in achieving the full spectrum of colors available through conventional dyeing. Researchers are making rapid progress, with recent breakthroughs expanding the color range to include vibrant blues and greens that were previously difficult to produce. Another area of development involves adapting the technology for different fabric types, as current systems work best with synthetic fibers.

The economic implications of widespread adoption could be profound. Traditional dye houses face significant transition costs, but forward-thinking manufacturers view this as an opportunity to future-proof their operations. As water scarcity becomes an increasing global concern and environmental regulations tighten, the business case for waterless dyeing grows stronger. Industry analysts predict the laser coloring sector will experience exponential growth within the next decade.

Beyond textiles, this technology has potential applications in packaging, automotive interiors, and even architectural materials. The same principles that create color on fabric could revolutionize how we color plastics, leather, and other surfaces. Researchers are exploring whether the technique could be adapted for use on natural materials like wood or stone.

As consumers become more environmentally aware, demand for sustainable products continues to rise. Laser-induced coloring offers brands a way to reduce their environmental impact while maintaining – and often enhancing – product quality. The technology aligns perfectly with circular economy principles by eliminating polluting processes and creating longer-lasting products.

The coming years will likely see laser coloring move from niche applications to mainstream adoption. As the systems become more sophisticated and cost-effective, they may render traditional dyeing methods obsolete. This transition won't happen overnight, but the direction is clear. The marriage of advanced laser technology with textile production points toward a future where beautiful, colorful fabrics leave no environmental stain.

Innovation often comes from unexpected intersections of technologies, and laser-induced coloring represents a perfect example. By bringing together photonics, materials science, and manufacturing engineering, this breakthrough addresses one of industry's most persistent environmental challenges. The result isn't just incremental improvement, but a fundamental reimagining of how we add color to our world.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025